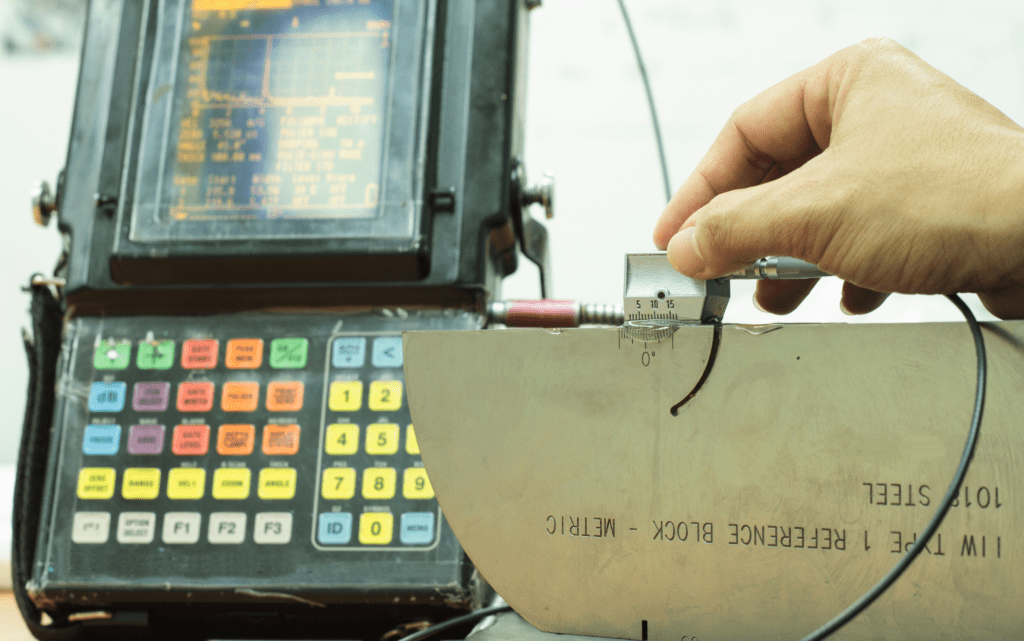

In the world of welding and engineering consulting in Edmonton, maintaining high-quality work and safety goes hand in hand with following established codes and standards.

These guidelines aren’t just about precision – they support safe, reliable, and enduring results.

At Qualimet, we’re here to simplify these codes for you, helping you understand their importance and how they impact your project.

Understanding Welding Codes and Standards

Welding uses codes and standards like ASME, CWB, AWS, CSA, API, and ISO, to develop critical and required documents such as Welding Procedure Specifications (WPS) to provide clear guidelines and specifications for welding processes, materials, and safety requirements.

These codes help create a foundation for reliable, quality work, setting work scopes that the owner or contractor follows to maintain consistency and dependability.

For companies in fields like construction and manufacturing, following these standards helps ensure the final products are dependable and compliant.

Overview of Major Welding Codes

There are several well-known welding codes across industries, each established by a respected organization.